Applications: NDT, Non-destructive testing

Explore unprecedented X-Ray imaging quality and pictures that literally cannot be overexposed.

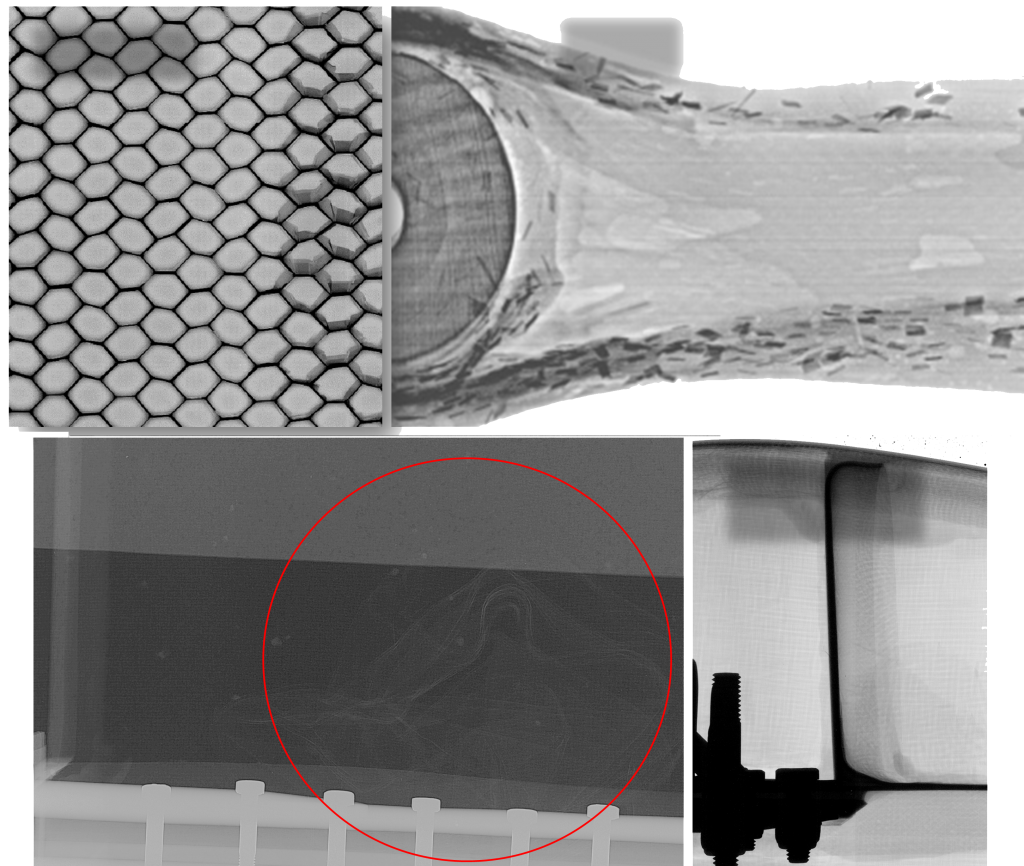

ADVACAM’s novel X-ray imaging technology is beneficial for inspecting light materials. As shown in the images, the high dynamic range allows to detect even a rose stem through a glass vase, a piece of cloth tissue left inside a composite plane wing, or PVC adhesive tape inside a pipe made of carbon fiber. The ability to detect objects with low attenuation inside ones with high attenuation is ideal for foreign object detection.

Standard radiographic X-ray imaging provides a black-and-white image of the inspected sample. Defects, impurities, or cracks may be observed only if the image’s resolution and signal-to-noise ratio (SNR) is appropriate. Advacam’s spectral X-ray imaging-based photon counting detectors provide additional material information about the samples with superior contrast and high spatial resolution, ideal for non-destructive testing (NDT).

Besides that: This approach enables us to see several different materials within one image. A single image of an atique puppet reveals wood, metal nails, a silk skirt, human hair, and puppet strings, a feat impossible with standard X-ray technology.

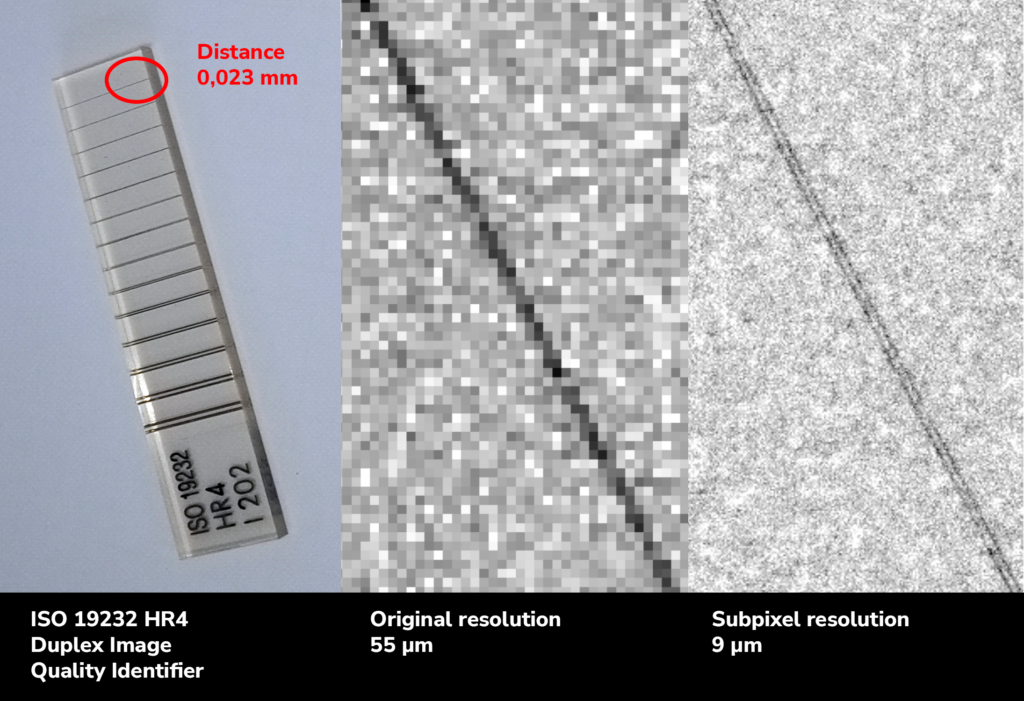

The size of the pixels of our cameras is 55 µm; therefore, the native resolution of our devices is 55 µm. However, it can be dramatically improved thanks to ADVACAM’s sophisticated data analysis and post-processing. It allows for achieving even sub-pixel resolution up to 9 µm in X-ray images. This resolution and exceptional sensitivity of CdTe sensors make our cameras an unbeatable X-ray imaging device.