Applications: NDT, non-destructive testing

Advacam produces novel photon-counting x-ray imaging detectors ideal for inspecting composites, such as carbon fiber reinforced polymers (CFRP). These detectors capitalize on their sensitivity to lower X-ray energies, which provide the best contrast in composites and reveal the most information about the internal structure.

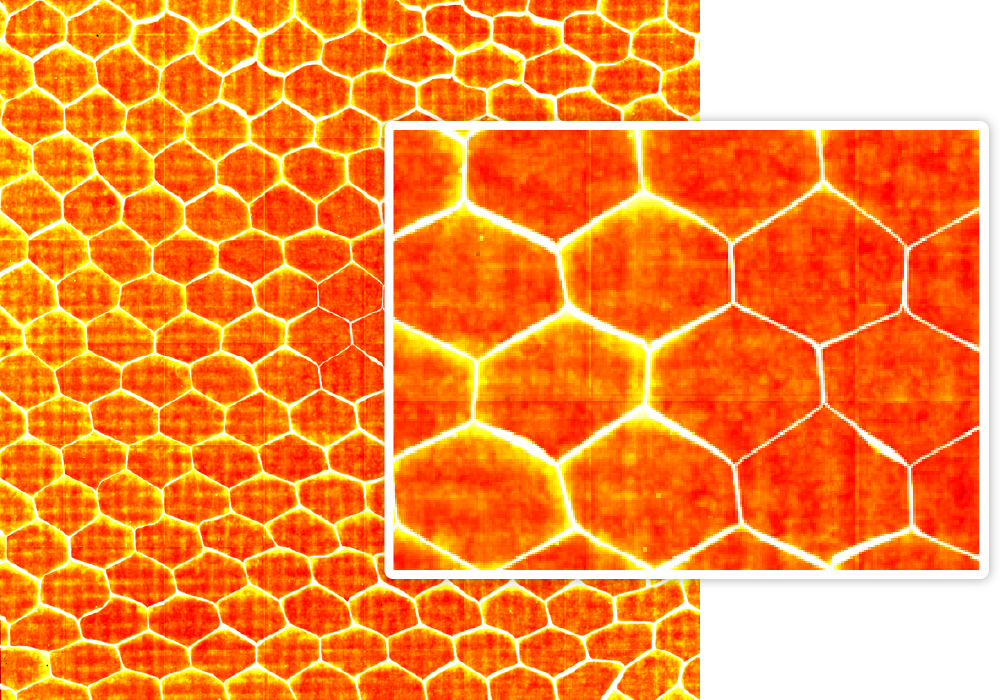

Light materials, like carbon fibers and epoxies, are quickly revealed in greater detail. Defects like core delaminations or layer delaminations, porosity, foreign objects, and micro-cracks are detectable with 55µm or better resolution.

Even a hard-to-detect defect, such as delaminations and kissing bonds, can be revealed using our detectors combined with the phase-contrast imaging method.

The sizes of X-ray cameras suitable for plastics and composite material inspection range from 14×14 mm up to 140×140 mm. Larger composite objects can be scanned with detector rows. These rows are combined out of blocks of 14×70 mm and can have length chosen depending on the application.