Further expansion of the rapidly growing market for photon-counting detectors requires a higher reliability of devices under hostile environments such as in industrial and space applications. Wire bonds are one of the most common causes of device failure. Thus, the Print 3Dproject aims to replace them by printed metallization or low temperature soldering. This technologies also will permit advanced assembly geometries like a particle tracker with applications e.g. in medicine, radiation detection, space research and security. Chronologically there are three following blocks of deliveries:

- Evaluate, improve and demonstrate a new technology for printing metallic chip-to-PCB and chip-to-chip contacts. This will a) replace vulnerable wire bonds and b) allow for new assembly geometries.

- Produce MediPix pixelated photon-counting radiation detector assemblies more resistant to mechanical, thermal and chemical stress.

- Use this technology to build a 3D particle tracker, resulting in a pocket-sized radiation detector with energy, spatial and directional reacts ution.

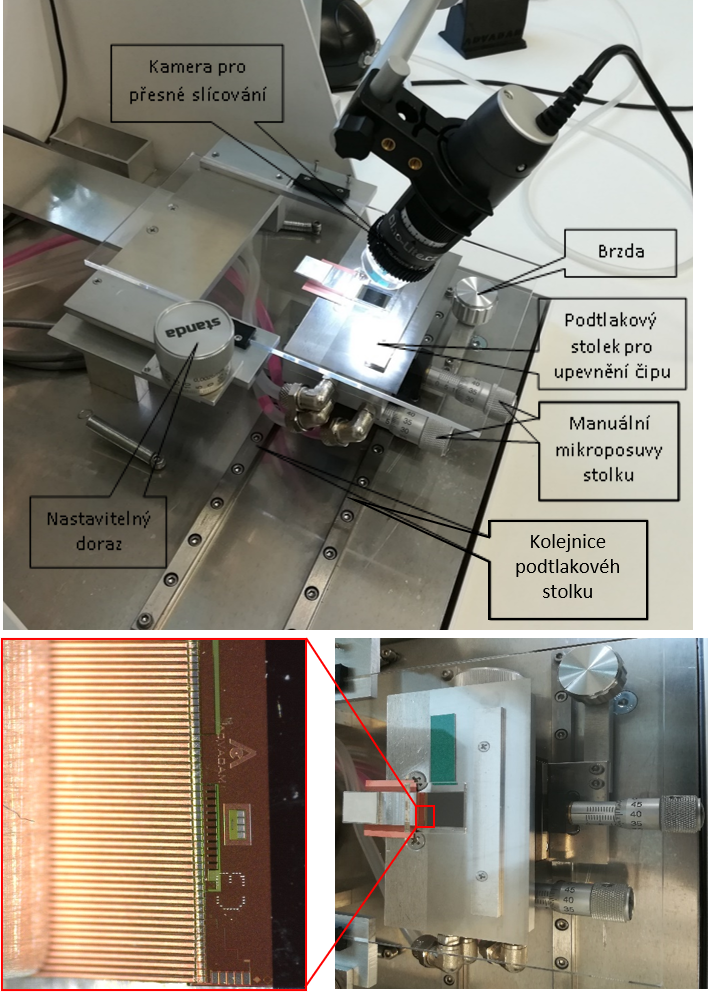

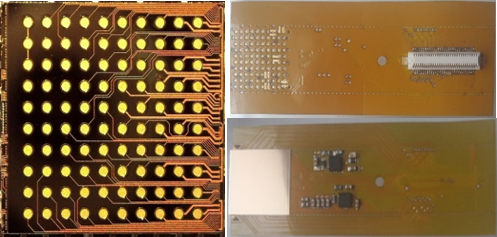

Besides originally aimed technology of printing contacts are followed new technological trends and finally four following technologies are developed in parallel to enhance chances for project success. 0th technology of 3D Jet direct contact print where Advacam designed and prepared perfectly aligned assembly, ready for printing contacts.

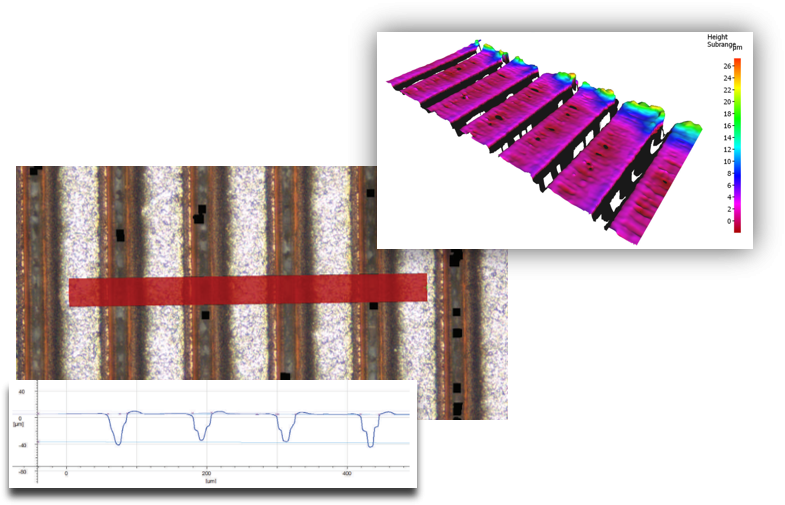

For PCB preparation used PicoLaser ablation, where space between contacts of 30 µm only reached

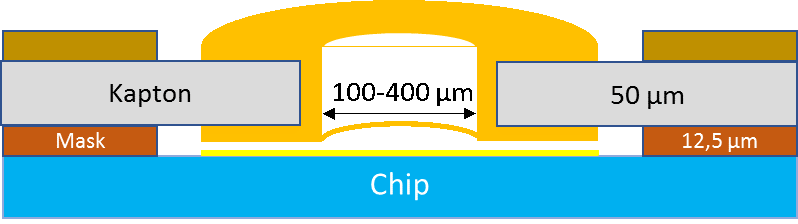

1st technology of contacting form back side of the chip by 3D Print (DoD mode) through holes in flex PCB

Specific redistribution mask on back side of MediPIX3 chip used to contact to specifically designed chipboard made from flex PCB

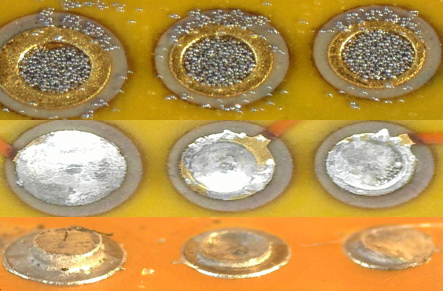

2nd technology of soldering by low temperature solder to back side of the chip, proven well contacted live chip. This back side contacting is specially suitable for large area detector allowing to assemble particular chip tiles into complete flat surface

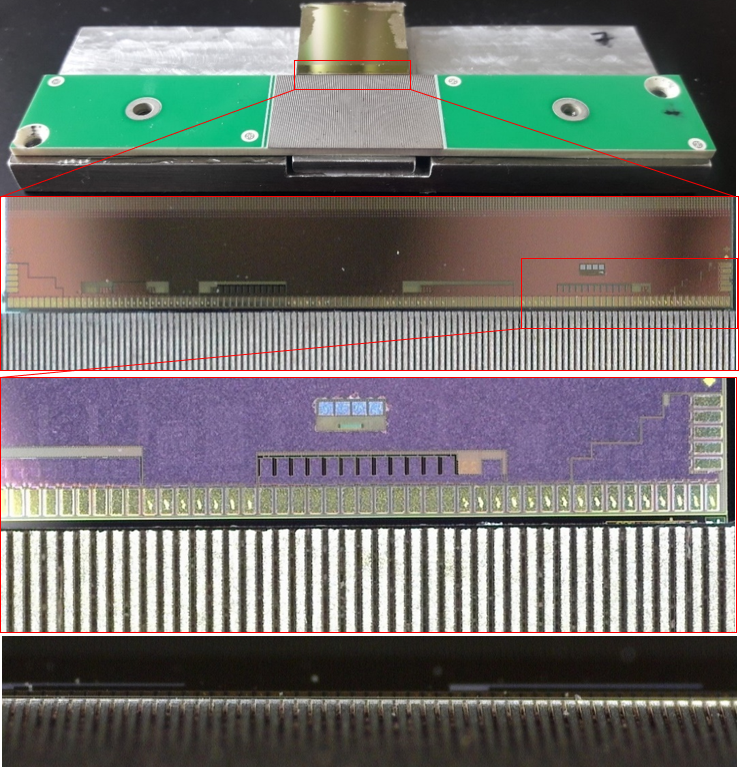

3rdtechnology of direct soldering of flex PCB to TimePIX chip front periphery by low temperature solder, for which a specific aligning and soldering station was designed and constructed