Applications: NDT, Non-destructive testing

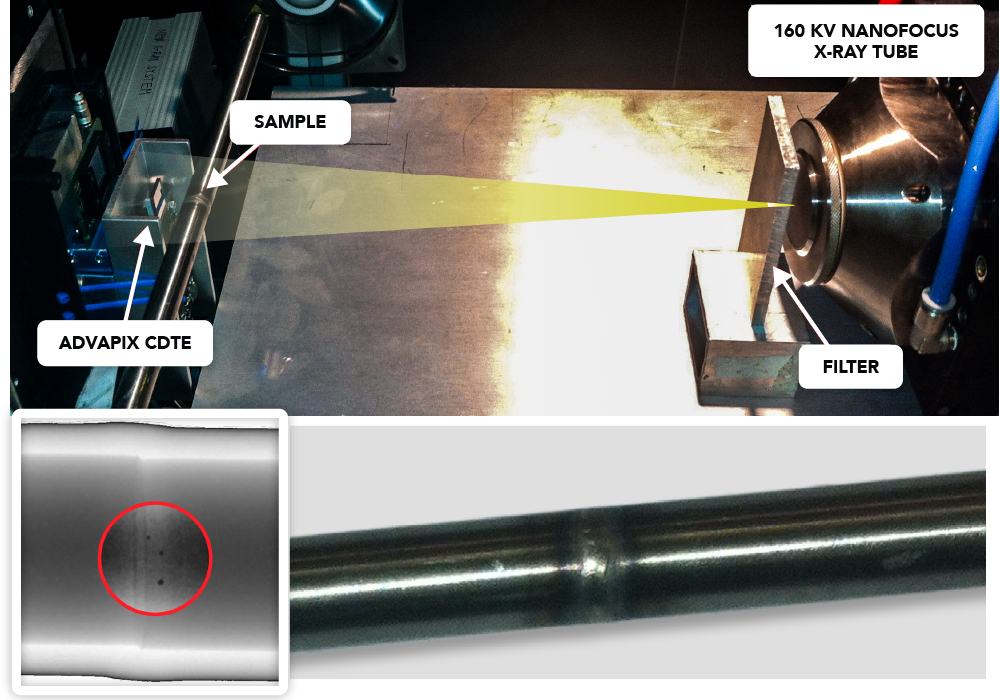

Advanced single-photon detectors enable quick and high-resolution inspection of welded vessels, stainless pipes, and other materials.

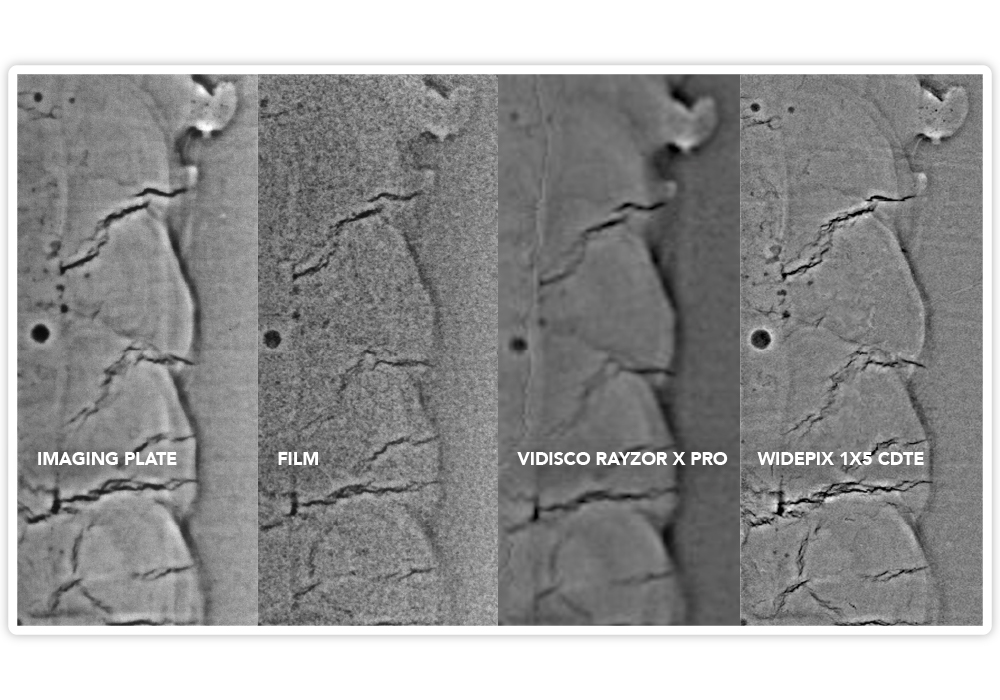

Precise welding requires highly sensitive and high-resolution inspection methods. Our detectors exhibit excellent properties in this field. For example, we present small details of the BAM-5 weld sample inspected with our detector with a resolution of 55 microns. The signal-to-noise ratio measured (SNRm) was 148 in the case of an 8.3 mm thick BAM-5 sample. Even thick structures of modern superalloys can be inspected in a fraction of the time required by standard inspection techniques.

The detectors achieve Class B image quality according to standard ISO 17636-2. Therefore, they are a perfect choice for cutting-edge digital radiography NDT systems. The detectors can be either operated in frame mode or time-delayed-integration mode, producing “endless” images as the detector moves along or around the object.

Our cameras can also quickly and accurately evaluate the quality of welded steel pipes, even when made from heavy and highly absorbing materials like stainless steel. Unlike traditional X-ray imagers, Advacam detectors are fully digital with an energy discriminator and counter in each pixel. That allows virtually noiseless counting of all ionizing particles at a much shorter exposure time.