Applications: Material Analysis

Our energy-sensitive X-ray cameras enable color radiography images to visualize different materials in your sample. Our multichannel imaging can be utilized for circuit board inspection, ore quality identification, and numerous other applications.

Do you need to determine the material composition of your sample? Minerals, alloys, polymers, electronics, batteries, or pigments? Our cameras are based on cutting-edge single X-ray photon counting sensors, and each detected photon is processed individually. This approach also allows measuring the wavelength of photons. It brings unprecedented image quality and new possibilities, such as material-sensitive X-ray imaging.

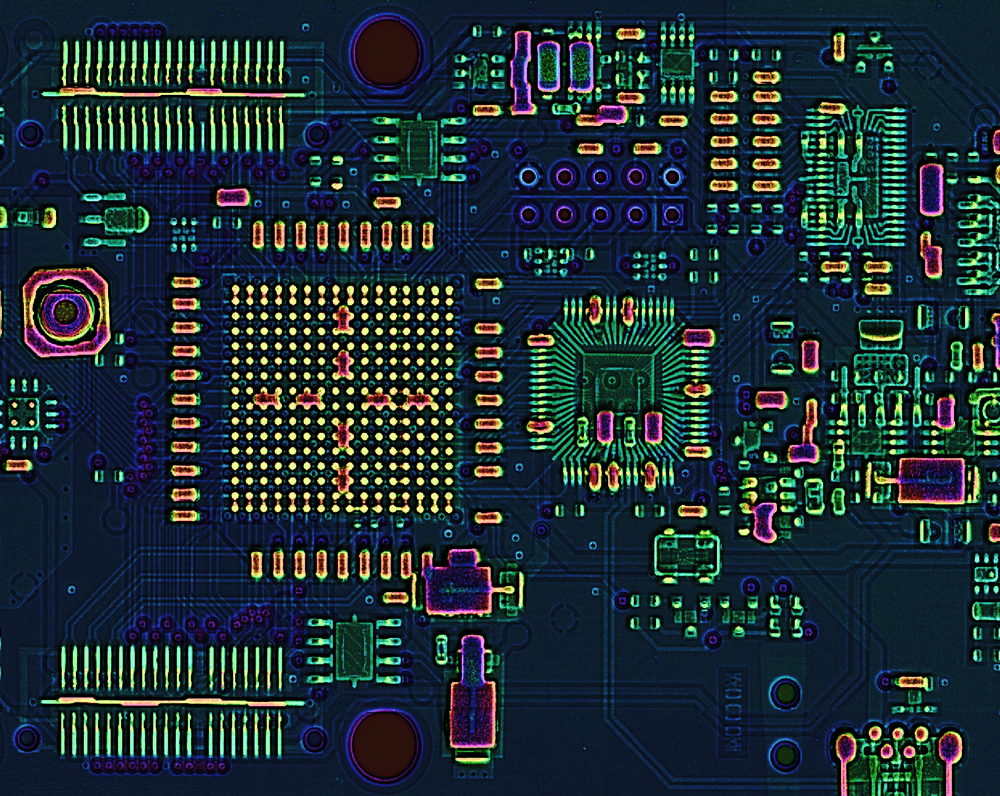

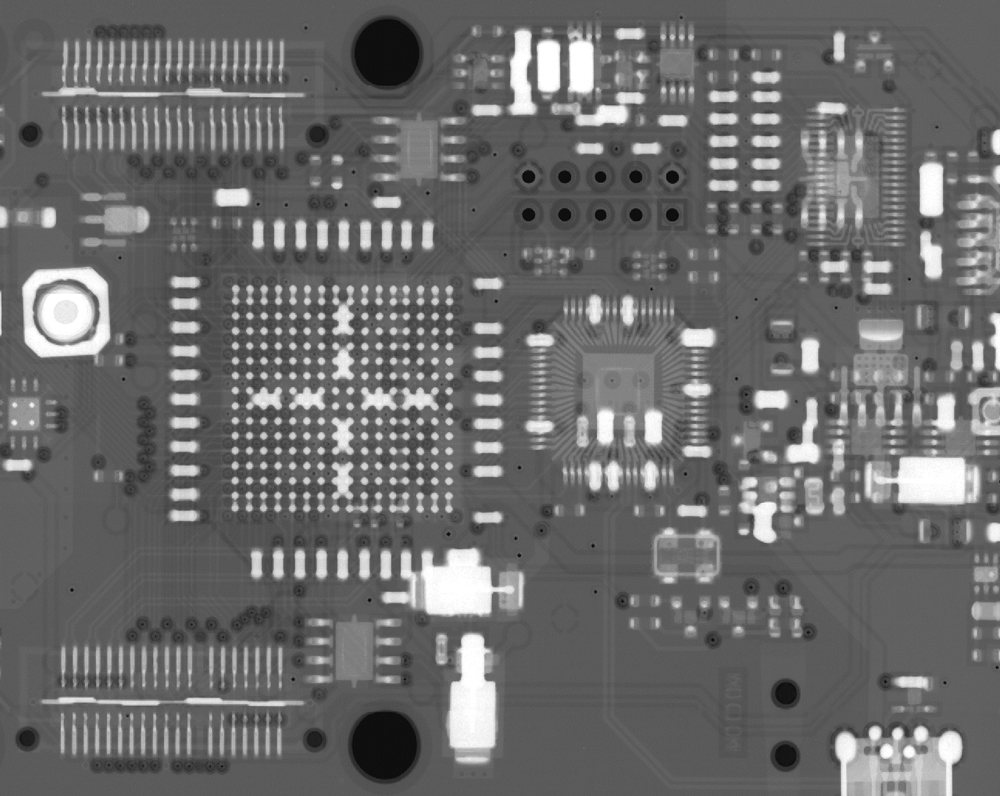

In the image, there is an FPGA circuit board visualized by our material-sensitive X-ray technology compared to a traditional grayscale X-Ray image. The yellow color identifies the solder; tantalum capacitors are pink, and many other colors regarding other present materials.

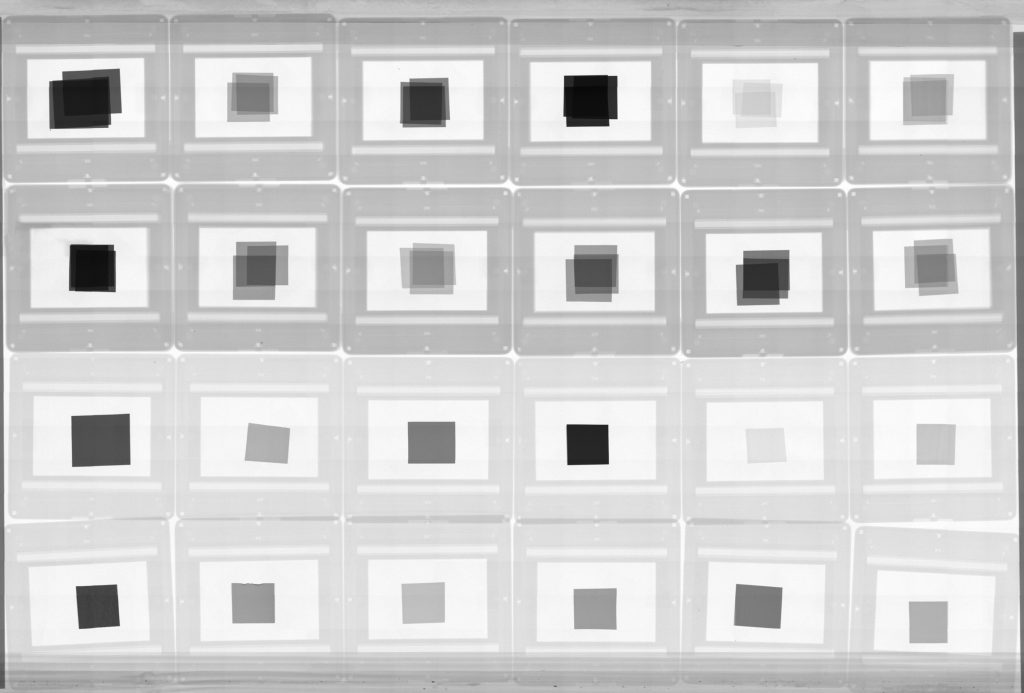

Various elements visualized by color x-ray radiography compared to traditional black and white x-ray imaging. In common grayscale X-ray images, some materials may appear at the same grey level even if they have an entirely different elemental composition. These differences are visible thanks to multichannel X-ray imaging.

The spectral X-ray imaging was evaluated using Radalytica robotic X-ray scanner that integrates Widepix 1×5 MPX3 CdTe detector. The scanner essentially extends the Widepix sensitive area from 70×14 mm2 to an area of up to 600×1200 mm2.