Applications: NDT, non-destructive testing

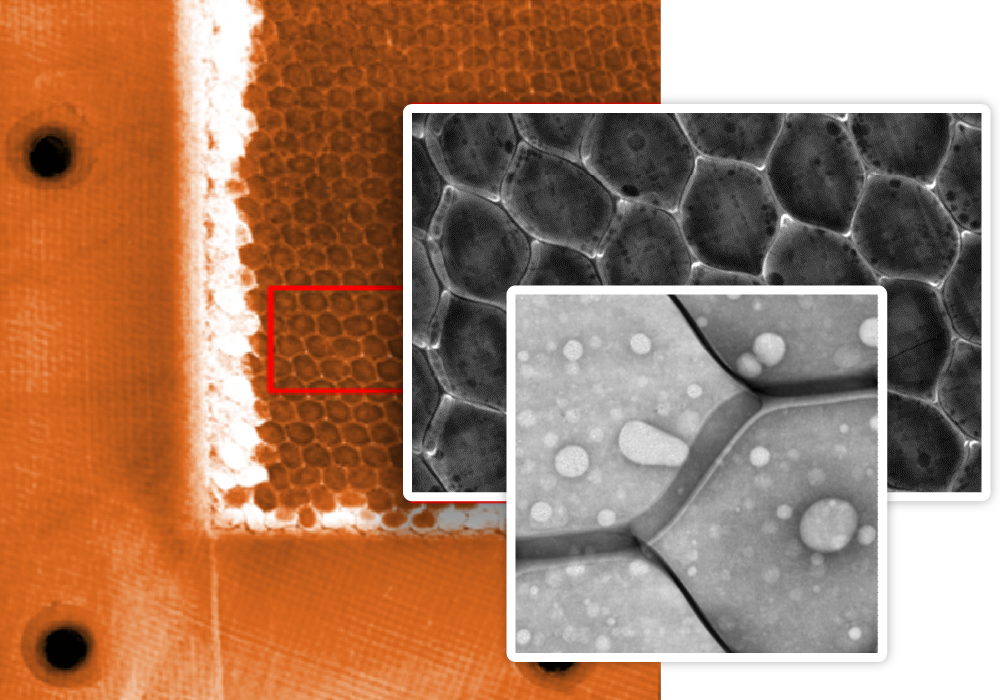

The single-photon X-ray imaging technology significantly enhances NDT capabilities for composite materials. It provides a powerful tool for industry applications to ensure the quality and reliability of critical components.

Modern industry requires tough, light, and reliable materials. That makes detecting defects, impurities, or cracks extremely important. However, traditional X-ray imaging systems for Non-destructive testing (NDT) are insufficient for modern materials like composites.

The next-generation photon-counting detectors, with “clever pixels” that process each detected x-ray photon, improve image quality, sensitivity, and material recognition in inspected samples. This has significant advantages for imaging since the photon-counting detectors do not suffer from the electronic noise that deteriorates the image quality in commonly available devices. Moreover, the pixels can also measure the wavelength of x-ray photons, opening new possibilities for „color radiography“ and recognizing different material types in inspected samples.