X-RAY IMAGING WITH EXTREME DYNAMIC RANGE

Explore unprecedented X-Ray imaging quality and pictures that literally cannot be overexposed.

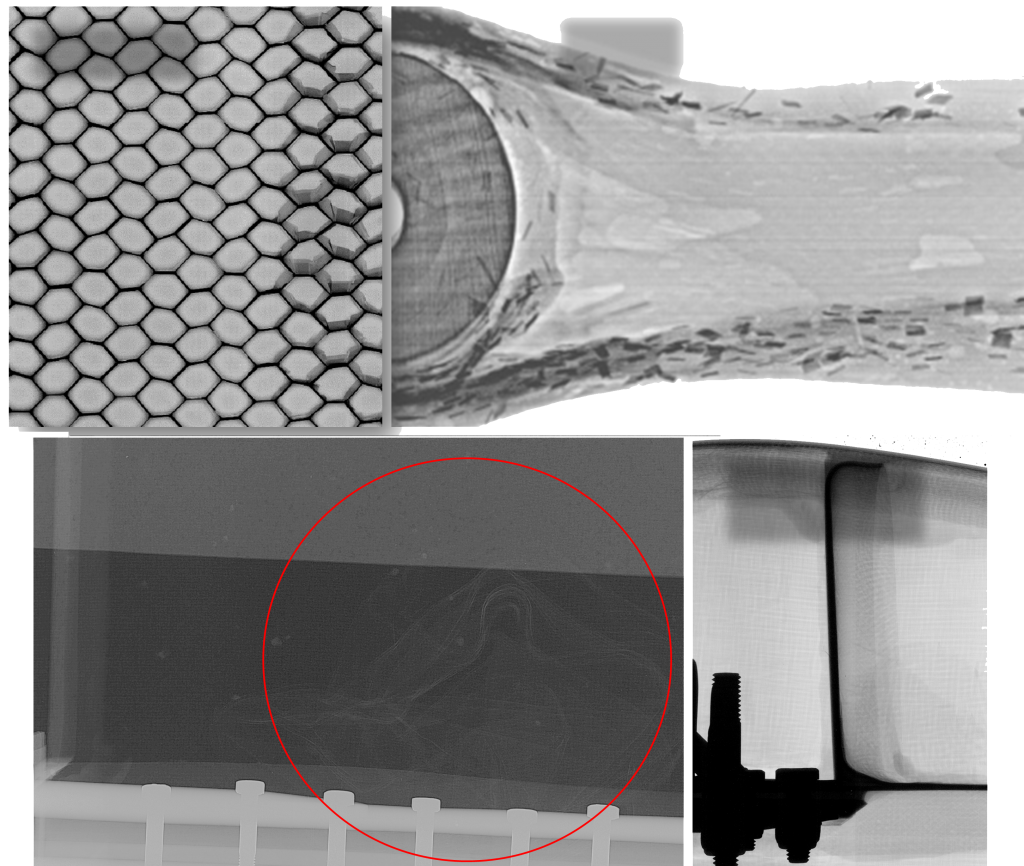

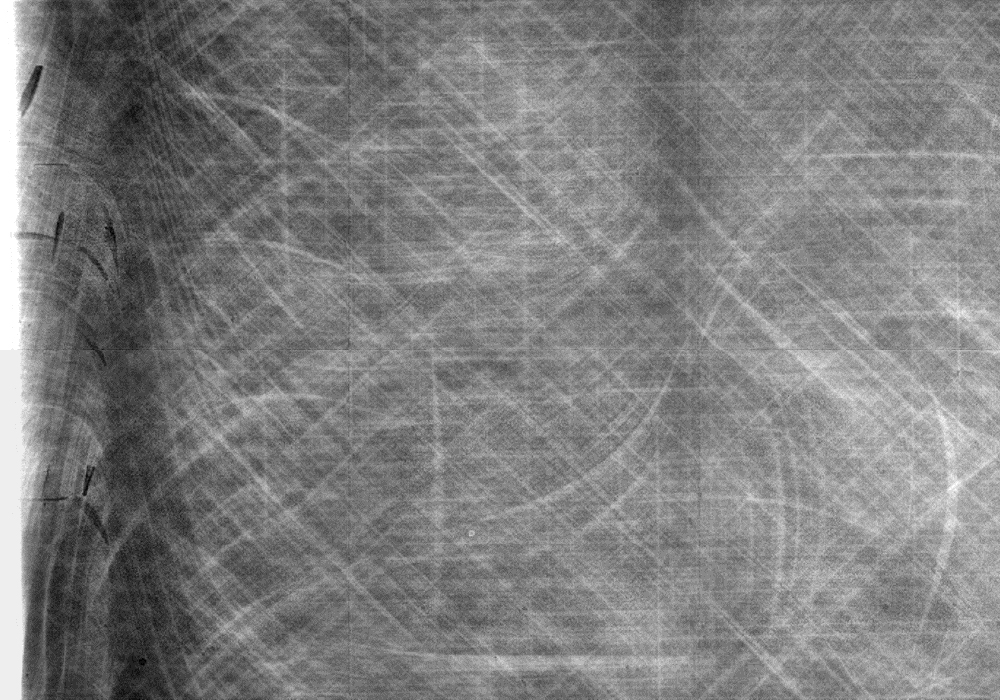

ADVACAM’s novel X-ray imaging technology is beneficial for inspecting light materials. As shown in the images, the high dynamic range allows to detect even a rose stem through a glass vase, a piece of cloth tissue left inside a composite plane wing, or PVC adhesive tape inside a pipe made of carbon fiber. The ability to detect objects with low attenuation inside ones with high attenuation is ideal for foreign object detection.

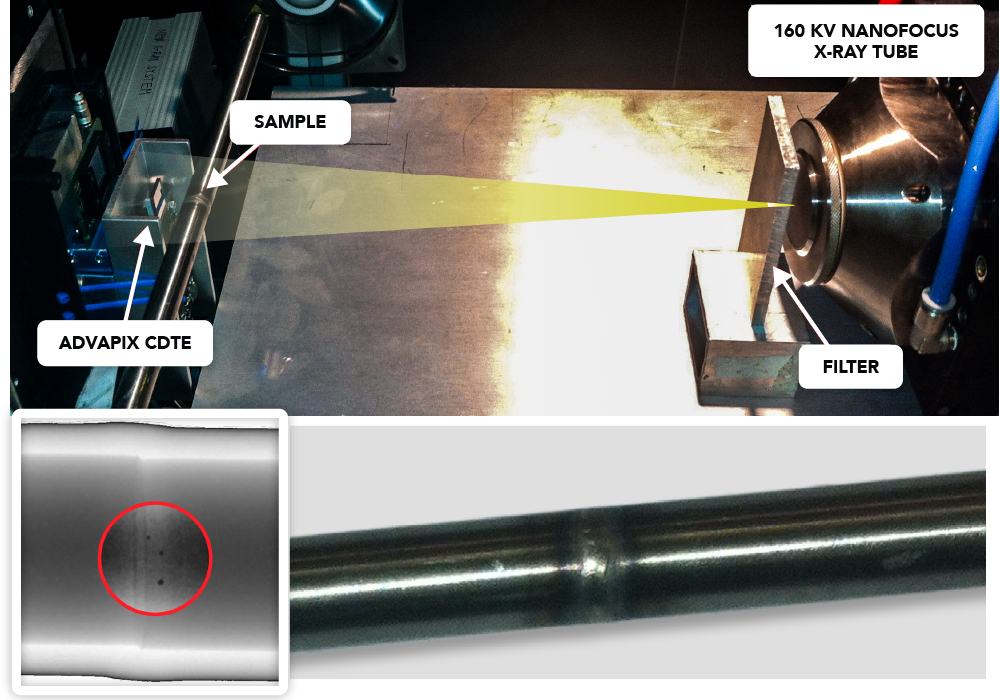

Standard radiographic X-ray imaging provides a black-and-white image of the inspected sample. Defects, impurities, or cracks may be observed only if the image’s resolution and signal-to-noise ratio (SNR) is appropriate. Advacam’s spectral X-ray imaging-based photon counting detectors provide additional material information about the samples with superior contrast and high spatial resolution, ideal for non-destructive testing (NDT).

Besides that: This approach enables us to see several different materials within one image. A single image of an atique puppet reveals wood, metal nails, a silk skirt, human hair, and puppet strings, a feat impossible with standard X-ray technology.

The size of the pixels of our cameras is 55 µm; therefore, the native resolution of our devices is 55 µm. However, it can be dramatically improved thanks to ADVACAM’s sophisticated data analysis and post-processing. It allows for achieving even sub-pixel resolution up to 9 µm in X-ray images. This resolution and exceptional sensitivity of CdTe sensors make our cameras an unbeatable X-ray imaging device.

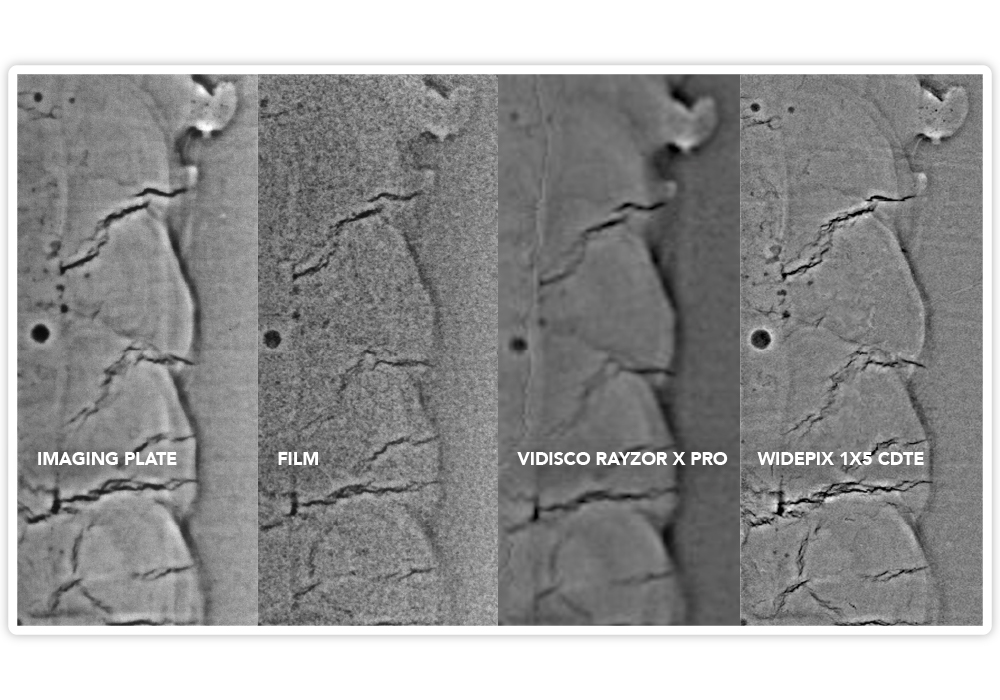

METAL WELD INSPECTION

Advanced single-photon detectors enable quick and high-resolution inspection of welded vessels, stainless pipes, and other materials.

Precise welding requires highly sensitive and high-resolution inspection methods. Our detectors exhibit excellent properties in this field. For example, we present small details of the BAM-5 weld sample inspected with our detector with a resolution of 55 microns. The signal-to-noise ratio measured (SNRm) was 148 in the case of an 8.3 mm thick BAM-5 sample. Even thick structures of modern superalloys can be inspected in a fraction of the time required by standard inspection techniques.

The detectors achieve Class B image quality according to standard ISO 17636-2. Therefore, they are a perfect choice for cutting-edge digital radiography NDT systems. The detectors can be either operated in frame mode or time-delayed-integration mode, producing “endless” images as the detector moves along or around the object.

Our cameras can also quickly and accurately evaluate the quality of welded steel pipes, even when made from heavy and highly absorbing materials like stainless steel. Unlike traditional X-ray imagers, Advacam detectors are fully digital with an energy discriminator and counter in each pixel. That allows virtually noiseless counting of all ionizing particles at a much shorter exposure time.

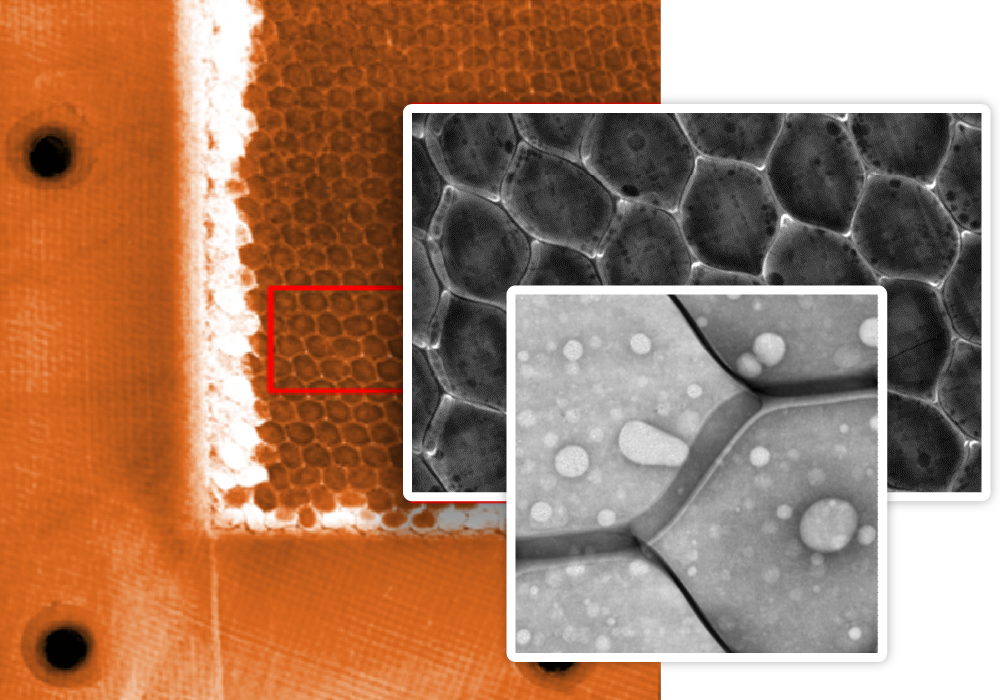

LIGHT COMPOSITE INSPECTION

The single-photon X-ray imaging technology significantly enhances NDT capabilities for composite materials. It provides a powerful tool for industry applications to ensure the quality and reliability of critical components.

Modern industry requires tough, light, and reliable materials. That makes detecting defects, impurities, or cracks extremely important. However, traditional X-ray imaging systems for Non-destructive testing (NDT) are insufficient for modern materials like composites.

The next-generation photon-counting detectors, with “clever pixels” that process each detected x-ray photon, improve image quality, sensitivity, and material recognition in inspected samples. This has significant advantages for imaging since the photon-counting detectors do not suffer from the electronic noise that deteriorates the image quality in commonly available devices. Moreover, the pixels can also measure the wavelength of x-ray photons, opening new possibilities for „color radiography“ and recognizing different material types in inspected samples.

UNCOVER COMPOSITE DELAMINATION

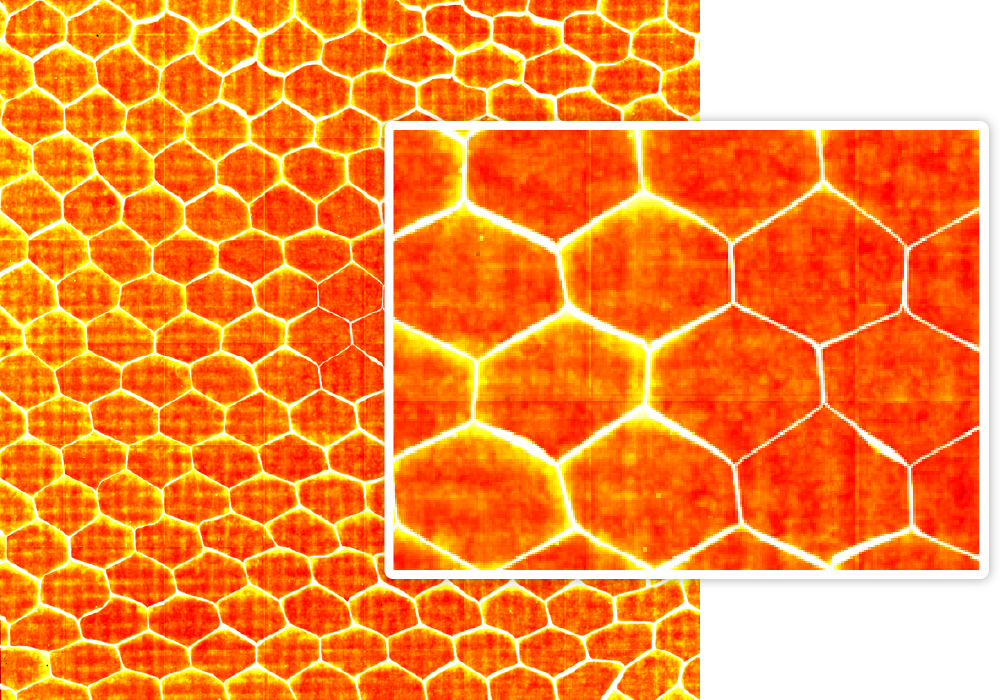

Advacam produces novel photon-counting x-ray imaging detectors ideal for inspecting composites, such as carbon fiber reinforced polymers (CFRP). These detectors capitalize on their sensitivity to lower X-ray energies, which provide the best contrast in composites and reveal the most information about the internal structure.

Light materials, like carbon fibers and epoxies, are quickly revealed in greater detail. Defects like core delaminations or layer delaminations, porosity, foreign objects, and micro-cracks are detectable with 55µm or better resolution.

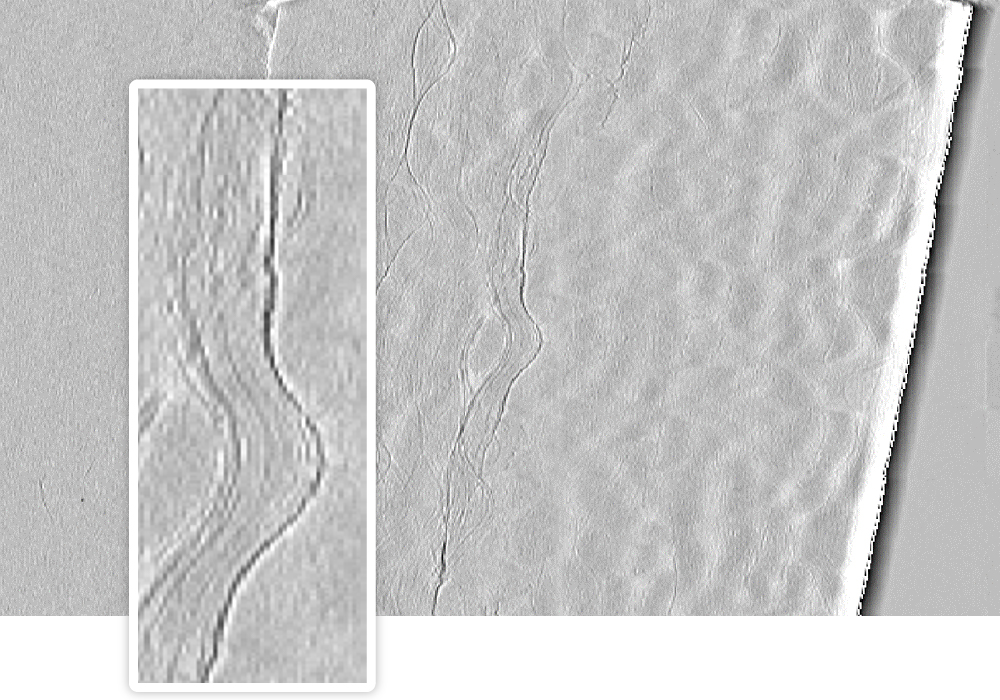

Even a hard-to-detect defect, such as delaminations and kissing bonds, can be revealed using our detectors combined with the phase-contrast imaging method.

The sizes of X-ray cameras suitable for plastics and composite material inspection range from 14×14 mm up to 140×140 mm. Larger composite objects can be scanned with detector rows. These rows are combined out of blocks of 14×70 mm and can have length chosen depending on the application.

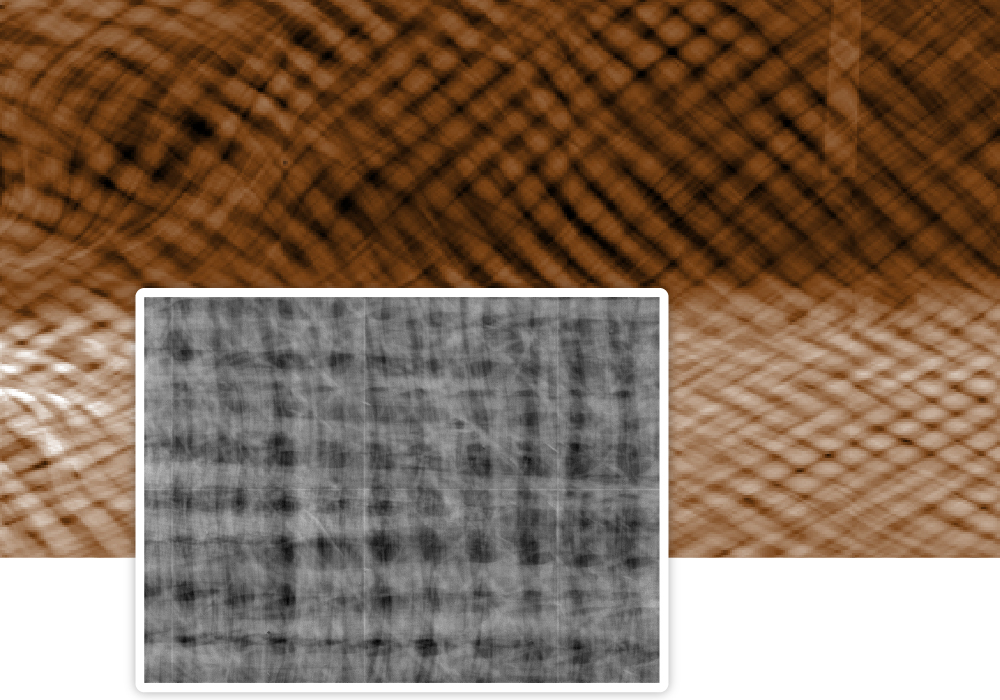

INSPECT COMPOSITE FIBER ORIENTATION

Inspect composite fiber orientation using low-energy X-rays, high sensitivity, and dynamic range in photon counting detectors for aerospace industry NDT.

The composite NDT takes advantage of the detector sensitivity to low X-ray energies that provide the best contrast in composites and carry the most information about the internal structure. Therefore, light materials such as carbon fibers, epoxies, etc., are quickly revealed in great detail. Defects such as porosity, foreign objects, and micro-cracks are easily detected with a resolution of 55 µm or better. Even challenging defects such as deep laminate wrinkles, kissing bonds, and delaminations can be found thanks to the excellent sensitivity of novel devices. Combining the sensitivity to low X-ray energy photons with the very high dynamic range of photon counting detectors creates a powerful tool for NDT in the airspace industry and elsewhere.

Robotic systems developed by Radalytica further expand the capabilities of photon-counting detectors. Contrary to the classical X-ray imaging setups, the automated system gives nearly absolute viewing angle flexibility. Therefore, these robots allow X-raying to localize defects from different perspectives better.

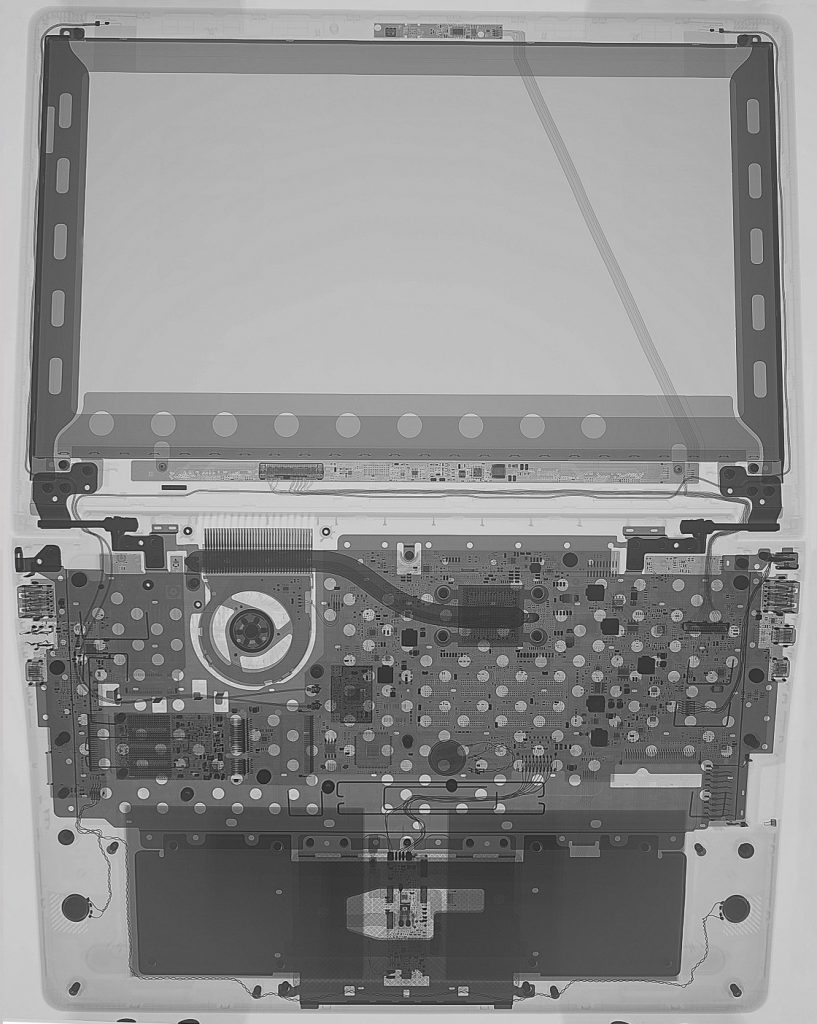

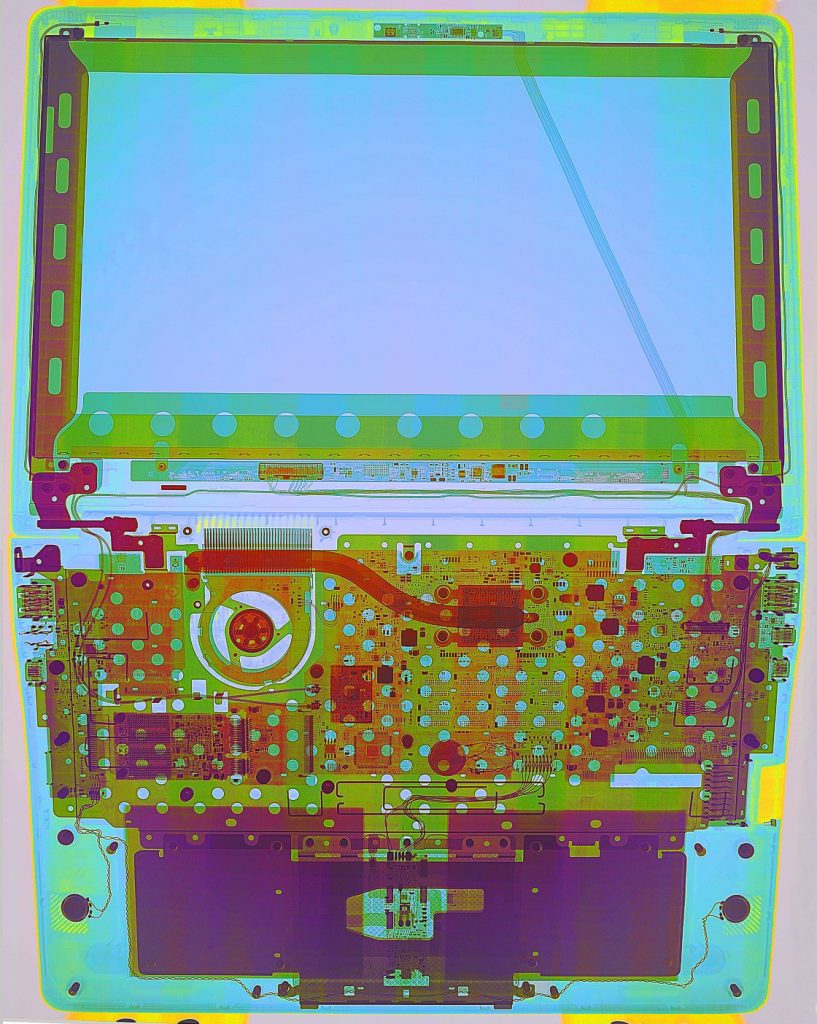

An example of the spectral X-ray imaging is the differentiation of materials in electronics. A laptop was scanned using the Widepix MPX3 CdTe detector on the robotic scanner. The resulting scan has 7852×9880 pixels, i.e., 77.6M pixels. Both the grayscale and “color” X-ray images are shown.

SPECTRAL IMAGING FOR NON-DESTRUCTIVE TESTING

Color X-ray imaging is now achievable. With our spectral detectors, we can measure the wavelength of each X-ray photon and determine the material being scanned. This technology revolutionizes non-destructive testing in electronics and various other complex devices, eliminating the need for disassembly.

Conventional X-ray images are grayscale, representing only variations in the density and thickness of materials. A thin layer of high-density, heavy material may appear at the same gray level as a thick layer of lightweight material, causing some features of samples to remain undetected. In contrast, energy-sensitive (spectral) X-ray imaging provides information on the elemental composition of the inspected object.

For example, this technique can be employed in non-destructive testing of electronics, where specific colors can distinguish different materials.