Get groundbreaking results with our photon-counting technology. We know that autumn is the season when academic institutions finalize next year’s budgets, and we have some great news! Our lead times have become much shorter and we can deliver all models by the end of the year.

We just participated in some traiblazing research, which got published in Scientific Reports – Nature’s most cited magazine.

Changing crystalline microstructure of iron is crucial for its mechanical properties in the finished product. X-ray diffraction has been an important method in metallurgy, but so far, it could only be done on the sample surface.

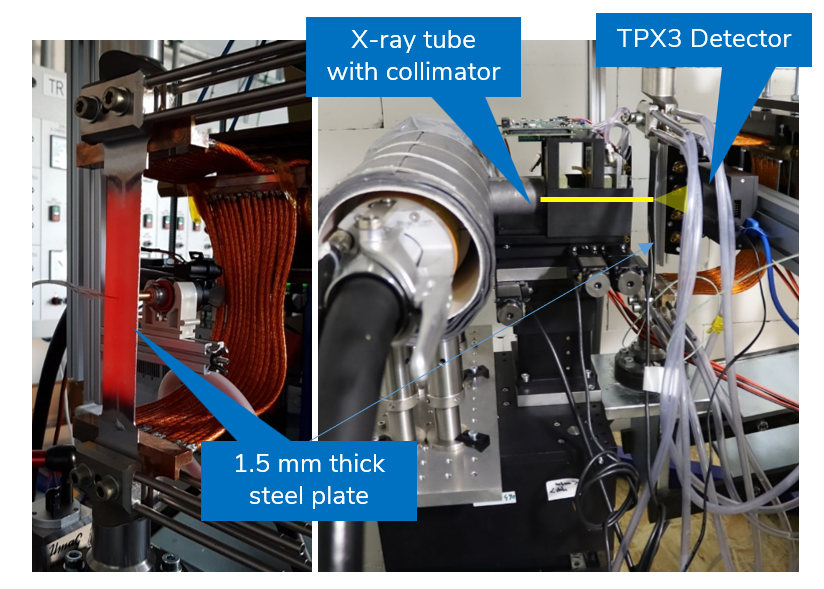

Jan Jakubek, together with Daniel Vavrik, Vjaceslav Georgiev, Bohuslav Masek, Ondrej Urban, Jan Sleichrt & Daniel Kytyr from Institute of Experimental and Applied Physics and University of West Bohemia, conducted an experiment: They monitored the crystalline composition of a 1.5 mm thick steel plate while changing its temperature from 25 to 750 °C and back within five minutes. They recorded XRD data using ADVACAM’s fully spectroscopic AdvaPIX detector. Then they compared the data with a mathematical model created by Jan.

The result?

Fitting the model to the data, the authors demonstrated that it is possible to observe microstructural changes within the metallic object volume in real time. They were able to accurately determine the presence of different allotropes (specifically austenite and ferrite) over time with precision better than 1%. A single measurement step can be performed in just 0.05 s. This method can be used for quality control in industry for the manufacturing of high-performance alloys, especially for metallurgical processes such as quenching, annealing, smithery, rolling, casting, etc.

Check the results in the graph or learn more in Scientific Reports.