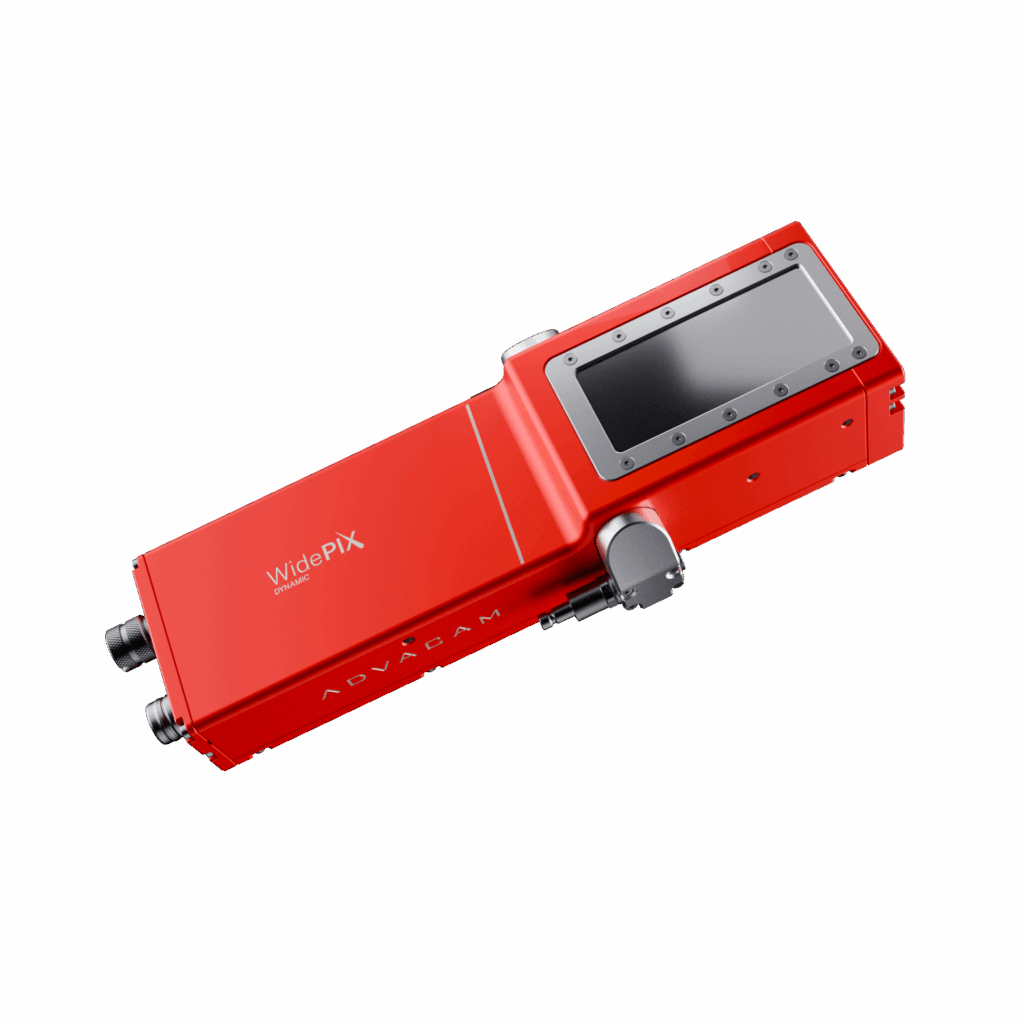

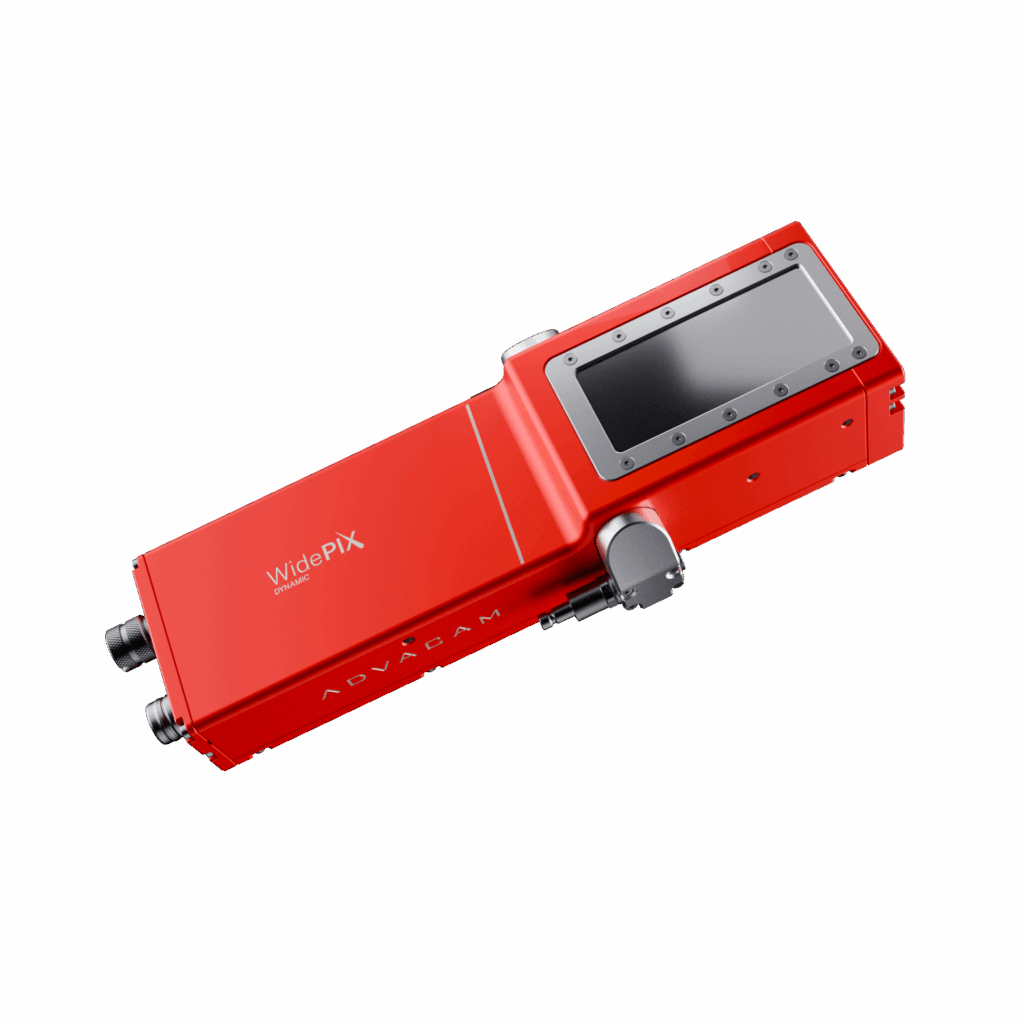

A multi-chip industrial scanner and imaging detector with the ability to provide spectral material-sensitive “color radiography“, introducing exceptional contrast and dynamic range. Based on Timepix2 photon-counting chips with silicon sensor layer.

A multi-chip industrial scanner and imaging detector with the ability to provide spectral material-sensitive “color radiography“, introducing exceptional contrast and dynamic range. Based on Timepix2 photon-counting chips with silicon sensor layer.

| Readout chip: | Timepix2 |

| Pixel pitch: | 55 μm |

| Max frame rate: | 150 fps (14 bits), 210 fps (10 bits), 500 fps (4 bits) |

| Thresholds per pixel: | 1 |

| Pixel mode of operation: | Counts 14 bits, Counts 10 bits, Counts 4 bits, Energy 14 bits (Integrated) |

| Counter depth: | 4, 10 or 14bits |

| Dimensions: | 228,5 x 92 x 42,5 mm |

| Weight: | 1700 g |

| Connectivity: | Ethernet POE, water cooling interface |

| Software: | PIXet Pro |

Product description

This photon-counting camera offers the highest contrast for X-ray imaging of all our products. It features a signal to noise ratio of over 2,000, frame rate of up to to 500 fps – depending on mode of operation (see parameters) – and bit depth and a high resolution – each pixel is just μm. These properties make it the best choice for imaging of both low and high-X-ray attenuating materials. It can detect energies as low as 3 keV.

The WidePIX DYNAMIC Industry detectors are suited for:

The WidePIX DYNAMIC line features a Timepix2 chips, each with a matrix of 65k square pixels of 55 μm pitch. They offer several operation modes (counts 14 bits, counts 10 bits, counts 4 bits and energy 14 bits) and selectable counter depths. The array of chips is almost gapless, the entire imaging area is fully sensitive without significant dead zones. The gap size is lower than 4 pixels.

More stable operation covers segment where current MPX3 based detectors fail because of insufficient contrast, such as imaging porosity, microcracks, or fibre to resin ratio. TPX2 based detector should have higher sensitivity due to lower minimal detectable energy (about 3 keV).

The cameras offer speed up to 500 frames per second. Thanks to its ability to collect spectral information directly, it allows for material-sensitive X-ray imaging in a single scan. The WidePIX DYNAMIC X-ray camera is available in multiple sizes and configurations to meet your specific needs.

The industrial optimization of WidePIX sets it apart:

The WidePIX DYNAMIC 5 layout offers a sensitive area arranged in one row of five chips. The sensitive area covers 327,680 pixels within the dimensions of 14 x 70 millimeters.

This layout offers the best properties for X-ray imaging of large areas using Time Delayed Integration. TDI can be applied for scanning samples on conveyor belts or other moving objects. The single-line chip arrangement allows for a higher frame rate and, therefore, fast scanning speed. These properties are suited for sorting machines.

The WidePIX DYNAMIC 10 layout offers a sensitive area arranged in two rows of five chips each. The sensitive area covers 655,360 pixels within the dimensions of 28 x 70 millimeters.

This layout offers the best properties for X-ray imaging using oversampling. Its compact size grants easy integration into instruments such as CT scanners or robotic CT systems. This makes it perfect to use in non-destructive testing equipment or highly sensitive medical X-ray imaging applications.

Typical energy range for photons: 8 – 60 keV

Detection efficiency for photons: Close to 100 % below 10 keV, around 50 % near 17 keV, and below 10 % beyond 40–50 keV.

Typical samples: Medium-density materials such as ceramics, polymer–metal composites, and thicker organic or composite specimens.

Typical applications:

Imaging

Particle tracking

Typical industries: Industrial NDT, materials research, electronics inspection, and applied science laboratories, XRD, CT and more

We have many references of implementing our cameras.

Discover all possibilities of Advacam cameras from real life case studies. Contact us and request our references.