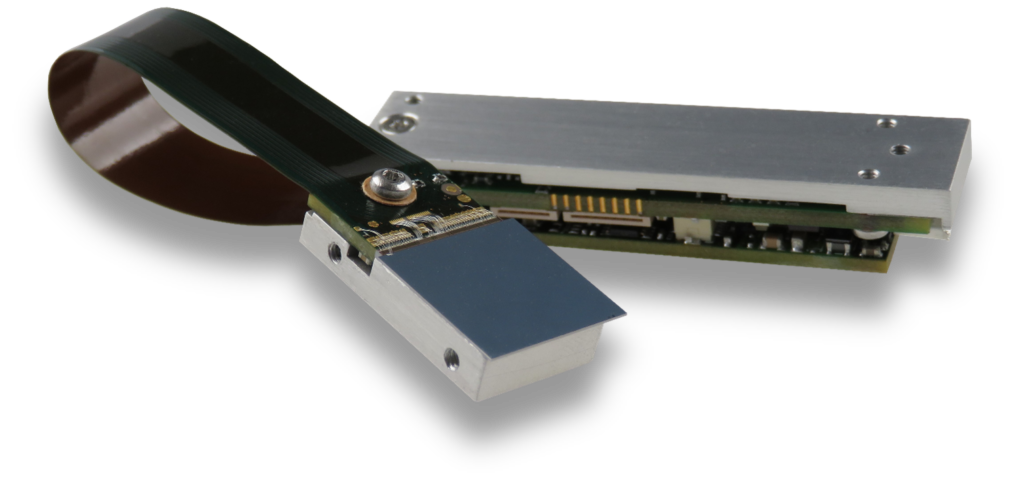

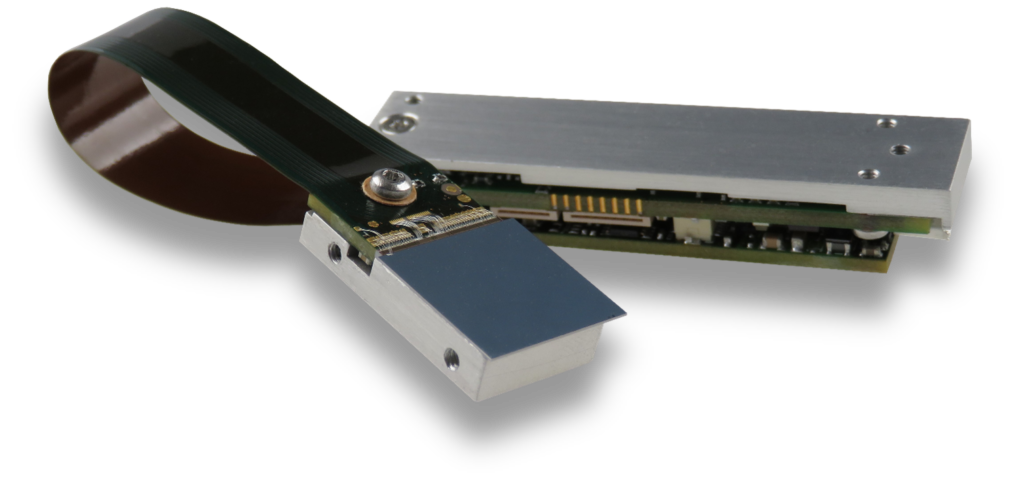

Miniature photon-counting detector with Timepix3 chip as a component for your system. The MiniPIX MAGIC Flex is a highly adaptable radiation detector, seamlessly integrating into any scientific or industrial setting.

Miniature photon-counting detector with Timepix3 chip as a component for your system. The MiniPIX MAGIC Flex is a highly adaptable radiation detector, seamlessly integrating into any scientific or industrial setting.

| Readout chip type: | Timepix3 |

| Pixel size: | 55 x 55 μm |

| Sensor resolution: | 256 x 256 pixels |

| Maximum frame rate: | 16 fps |

| Maximum hit rate: | 2.35 x 10^6 pixels/s |

| Time Resolution: | 1.6 ns |

| Min Detectable Energy: | 3 keV (Si) and 5 keV (CdTe) |

| Pixel Mode of Operation: | Time-over-Threshold, Time-of -Arrival |

Product description

The MiniPIX MAGIC Flex detector incorporates single Timepix3 chip (256 x 256 pixels with a pitch of 55 μm) with a Silicone or Cadmium Telluride sensor according to customer preference. Custom types such as GaAs or CZT are possible too.

The detector is position, energy, and time-sensitive. This means it digitally registers its position, energy, time of arrival, and track shape of every single particle that comes in contact with the sensor. Other information can be calculated form this data, such as particle type, direction of flight, its energy, or charge. The device collects data in pixel mode, which means each hit is read out immediately at a maximal rate of 2.3 million hit pixels per second. This makes the MiniPIX MAGIC detector ideal solution for all particle tracking aplications

The Flex solution removes the solid housing to adapt the detector for integration into large industrial systems. The MiniPIX MAGIC Flex detector is connected via USB interface. It is controlled in PIXet Pro software, which is provided for free. It runs on all major operating systems (MS Windows, Mac OS and LINUX). API integration is possible for other programmes.

Where can you use the MiniPIX MAGIC Flex photon-counting camera? For material analysis or radiation monitoring.

Typical energy range for photons: 3 – 20 keV

Detection efficiency for photons: Nearly 100 % below 5 keV, decreasing rapidly above 10 keV; <10 % efficiency beyond 30 keV.

Typical applications:

Particle tracking

Typical industries: research, electron microscopy (Life sciences, biomedical imaging, microelectronics research, materials testing of low-Z materials), and more

Typical energy range for photons: 5 – 40 keV

Detection efficiency for photons: Nearly 100 % below 8 keV, around 50 % at ~15 keV, gradually decreasing toward 30 keV; <10 % efficiency beyond 50 keV.

Typical samples: Light to medium-density materials such as organic samples, polymers, ceramics, and composite structures.

Typical applications:

Imaging

Particle tracking

Typical industries: Material science, electronics inspection, life-science imaging, cultural-heritage analysis, and general laboratory research, space-environment monitoring, Space-radiation and dosimetry experiments, XRD, CT, and more

Typical energy range for photons: 8 – 60 keV

Detection efficiency for photons: Close to 100 % below 10 keV, around 50 % near 17 keV, and below 10 % beyond 40–50 keV.

Typical samples: Medium-density materials such as ceramics, polymer–metal composites, and thicker organic or composite specimens.

Typical applications:

Imaging

Particle tracking

Typical industries: Industrial NDT, material research, electronics inspection, and applied science laboratories, space-environment monitoring, Space-radiation and dosimetry experiments, XRD, CT and more

Typical energy range for photons: 20 – 150 keV

Detection efficiency for photons: Nearly 100 % up to about 80 keV, remaining above 50 % around 120 keV, and gradually decreasing beyond 150 keV; still responsive at several hundred keV.

Typical samples: Dense materials such as metals, minerals, ceramics, and thick composite structures.

Typical applications:

Imaging

Particle tracking

Typical industries: Industrial NDT, materials characterization, mining and geology, nuclear research, and scientific instrumentation, XRD, XRF, CT, and more

We have many references of implementing our cameras.

Discover all possibilities of Advacam cameras from real life case studies. Contact us and request our references.